Industrial Razor blades | Film Slitting Blades | Converting Blades

Cutting Edge Solutions for Precision Industries

Welcome to Hardedge Tool, your premier destination for top-quality industrial razor blades, film slitting blades, and converting blades. With over 50 years of industry experience, we specialize in providing cutting-edge solutions to enhance efficiency and precision in various sectors, including film, foil, food, paper, fiber, and flexible packaging. Explore our range of high-performance blades and coatings designed to elevate your cutting processes to new heights of excellence.

Years of Expertise

Happy Customers Served

Our Strengths

Precision

Delivering accuracy and reliability in every cut, ensuring quality and performance for your industrial needs.

Innovation

Constantly pushing boundaries to develop cutting-edge solutions that drive efficiency and productivity for our clients.

Quality

Committed to excellence, our blades undergo rigorous testing to guarantee unmatched durability and longevity.

Customer Satisfaction

Putting our customers first, we provide exceptional service and support, ensuring your needs are met with precision and care.

Our Story

Welcome to the heart of our story. At Hardedge Tool, our legacy is built on over five decades of dedication and expertise in the industrial cutting industry. From our humble beginnings to our position today as a trusted leader in precision cutting solutions, every chapter of our journey is marked by a relentless pursuit of excellence and innovation. Step into our world and explore the rich tapestry of our history.

Rooted in a passion for precision and driven by a commitment to customer satisfaction, Hardedge Tool is more than a company – it’s a testament to the power of perseverance and ingenuity. Our journey is defined by our unwavering focus on quality, reliability, and continuous improvement. Join us as we continue to shape the future of industrial cutting, one precise cut at a time.

Words from Our Clients

Optimize Your Cutting Operations Today

Discover the power of precision with Hardedge Tool. Streamline your processes and boost productivity with our tailored cutting solutions. Contact us now!

Why Choose Hardedge Tool?

At Hardedge Tool, we proudly distinguish ourselves as the ultimate destination for cutting solutions. Boasting an unparalleled legacy of over 50 years in the industry, our commitment to excellence knows no bounds. We place utmost importance on precision, quality, and unwavering customer satisfaction, ensuring that each interaction with us surpasses your loftiest expectations. From our revolutionary products to our unwaveringly dedicated team, we are resolutely poised to elevate your cutting processes to unprecedented heights and propel your triumphs to new horizons.

Our illustrious clientele speaks for itself, as we proudly serve as trusted partners to 15 out of the coveted top 25 companies listed in the esteemed Plastic News 2023 Film and Sheet Ranking. What’s more, an astounding 40 customers from the prestigious top 100 rankings have placed their unwavering trust in our cutting solutions. These remarkable endorsements bear testament to our sterling track record, forged through years of delivering cutting-edge solutions to a diverse spectrum of industries. The loyalty and trust we have earned from our esteemed clients are badges of honor that we wear with utmost pride.

By choosing Hardedge Tool, you are not merely selecting a partner, but rather embracing the embodiment of reliability, innovation, and an unwavering dedication to your triumphs. We are poised to become an indispensable asset, propelling your success to unprecedented heights.

Expert Team

Experienced professionals dedicated to delivering innovative cutting solutions tailored to your specific requirements and industry standards.

Quality Assurance

Rigorous testing and highest quality materials ensure our blades meet the highest standards of durability, reliability, and performance.

Customer Satisfaction

Our commitment to exceptional service means we prioritize your needs, providing support and solutions that exceed expectations, every time.

Our Cutting-edge Services

Cutting Solutions

Innovative cutting solutions delivering efficiency and precision, from blade selection to process optimization, ensuring superior performance across applications.

Razor Slitting Solutions

Precision razor slitting services tailored to your needs, ensuring clean and accurate cuts for various materials in industrial applications.

Circular / Shear / Score & Core Blades Services

Comprehensive services for circular, shear, score, and core blades, optimizing cutting processes for enhanced efficiency.

Special Industry Blades Offerings

Customized solutions for specialized industry blades, meticulously designed to meet the unique cutting requirements of diverse sectors with unparalleled precision and efficiency.

Our Process

1

Analysis

Thorough assessment of your cutting needs to identify precise requirements and optimal solutions.

Design

Customized blade design tailored to your specifications, ensuring maximum performance and efficiency.

Manufacturing

State-of-the-art manufacturing processes to produce high-quality blades with precision and consistency.

Testing

Stringent quality testing to guarantee durability, reliability, and superior performance in real-world cutting applications.

Our Team

Will

Randy

Andrew

Frequently Asked Questions

How do I choose the right blade for my cutting needs?

Consider factors such as material type, thickness, and application requirements. Our experts can guide you through the selection process.

Can your blades be sharpened or reconditioned?

Yes, many of our blades are designed to be reconditioned multiple times, extending their lifespan and cost-effectiveness.

What industries do you serve?

We cater to a wide range of industries including film, foil, food, paper, fiber, and flexible packaging, among others.

How long does it take to receive an order?

Stock items are typically shipped within one business day. For custom orders, lead times may vary depending on specifications.

Do you offer blade sharpening services?

Yes, we provide sharpening services to ensure optimal blade performance and longevity.

What is the difference between your blade coatings?

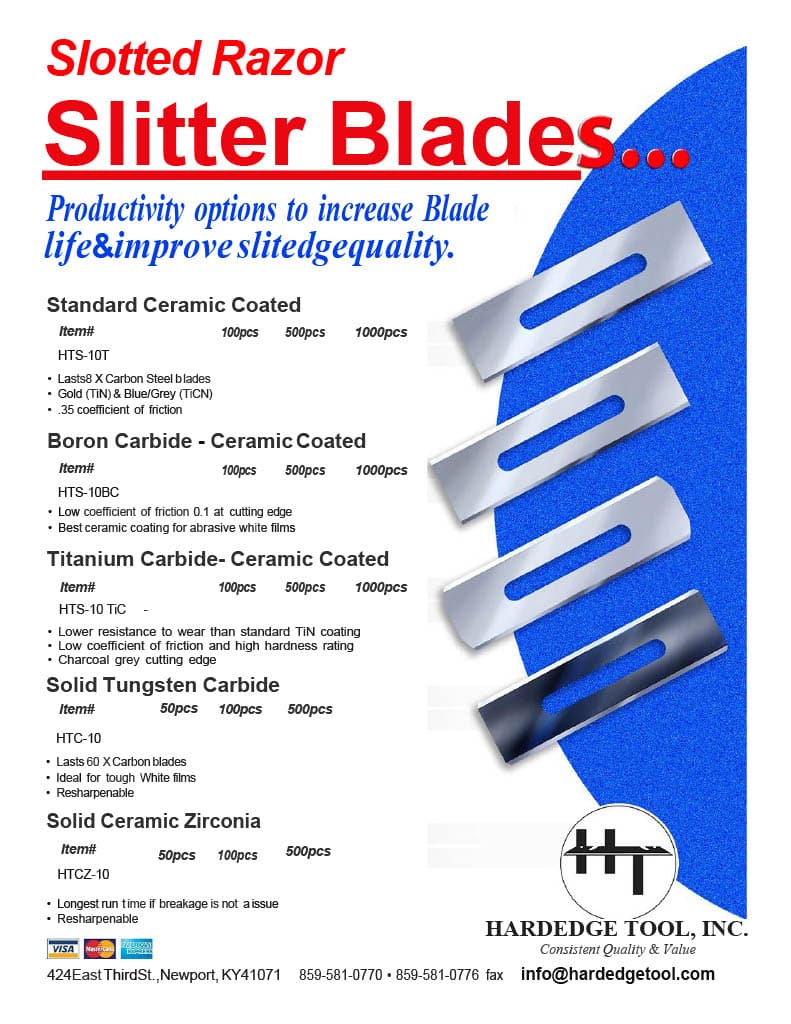

Hardedge Tool offers different blade coatings that provide varying levels of durability and resistance to specific cutting challenges. We offer the following Slitter Blades:

Standard Ceramic

Boron Carbide – Ceramic

Titanium Carbide – Ceramic Coated

Solid Tungsten Carbide

Solid Ceramic Zirconia