Precision Three Hole / Euro Razor Slitter Blade

Discover precision-engineered three-hole and Euro razor slitter blades designed to revolutionize your cutting processes. Experience superior sharpness and durability, ensuring flawless cuts for your specialized applications.

Superior Three Hole / Euro Razor Slitter Blades

Our Three Hole / Euro Razor Slitter Blades are engineered to deliver unparalleled performance, setting the standard for precision cutting in the industry. With a focus on durability and reliability, these blades ensure consistent results with every use, maximizing productivity and minimizing downtime.

Featuring state-of-the-art design and manufacturing techniques, our Three Hole / Euro Razor Slitter Blades are optimized to meet the demands of even the most challenging cutting tasks. Whether you’re slitting film, foil, paper, or other materials, you can trust in the exceptional quality and performance of our blades to streamline your operations and achieve superior results.

Three Hole / Euro Razor Slitter Blades

| Part # | Size | Square or Round Corners | Material | Edge Coating |

| HTS-3H | 1.693″ x .874″ x .012″ | Both | Stainless Steel | uncoated |

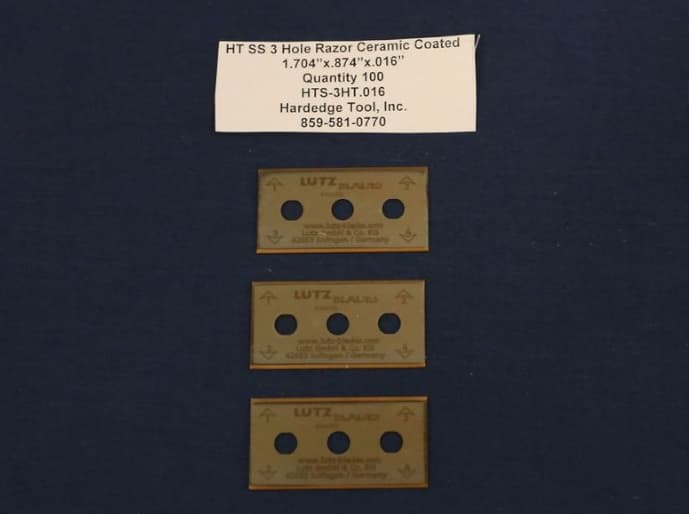

| HTS-3HT | 1.693″ x .874″ x .012″ | Both | Stainless Steel | “Ceramic Gold” TiN edge coating |

| HTS-3H TiC | 1.693″ x .874″ x .012″ | Square | Stainless Steel | Titanium Carbide (TiC) edge coating |

| HTS-3H.006 | 1.693″ x .874″ x .006″ | Both | Stainless Steel | uncoated |

| HTS-3HT.006 | 1.693″ x .874″ x .006″ | Both | Stainless Steel | “Ceramic Gold” TiN edge coating |

| HTS-3H.008 | 1.693″ x .874″ x .008″ | Both | Stainless Steel | uncoated |

| HTS-3HT.008 | 1.693″ x .874″ x .008″ | Both | Stainless Steel | “Ceramic Gold” TiN edge coating |

| HTS-3H.016 | 1.693″ x .874″ x .016″ | Square | Stainless Steel | uncoated |

| HTS-3HT.016 | 1.693″ x .874″ x .016″ | Square | Stainless Steel | “Ceramic Gold” TiN edge coating |

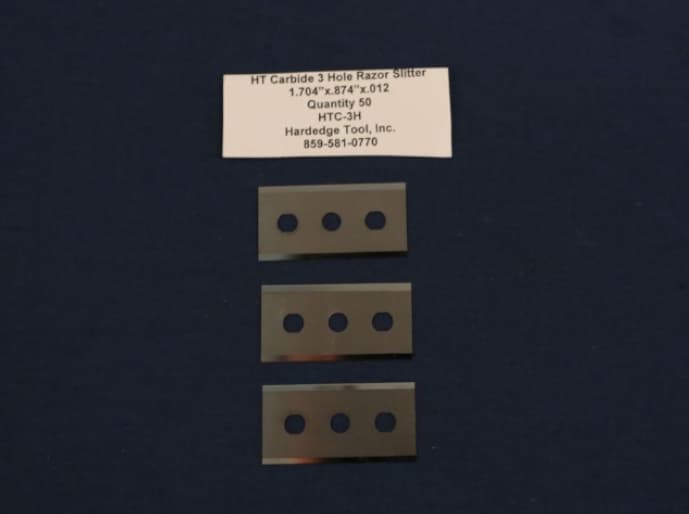

| HTC-3H | 1.693″ x .874″ x .012″ | Square | Tungsten Carbide | uncoated |

| HTC-3H.008 | 1.693″ x .874″ x .008″ | Square | Tungsten Carbide | uncoated |

| HTCZ-3H | 1.693″ x .874″ x .012″ | Square | Ceramic Zirconia | uncoated |

Words from Our Clients

Why Choose Hardedge Tool?

At Hardedge Tool, we stand out as your premier choice for cutting solutions. With over 50 years of industry experience, our commitment to excellence is unmatched. We prioritize precision, quality, and customer satisfaction, ensuring that every interaction with us exceeds your expectations. From our innovative products to our dedicated team, we are here to elevate your cutting processes and drive your success forward.

Our track record speaks volumes. With a long history of delivering top-notch cutting solutions to a wide range of industries, we have earned the trust and loyalty of our clients. When you choose Hardedge Tool, you’re choosing reliability, innovation, and a partner dedicated to your success.

Expert Team

Experienced professionals dedicated to delivering innovative cutting solutions tailored to your specific requirements and industry standards.

Quality Assurance

Rigorous testing and highest quality materials ensure our blades meet the highest standards of durability, reliability, and performance.

Customer Satisfaction

Our commitment to exceptional service means we prioritize your needs, providing support and solutions that exceed expectations, every time.

Ready to Upgrade Your Cutting Process?

Unlock the potential of your cutting operations with our premium-quality blades. Experience precision, reliability, and efficiency like never before.

Our Cutting-edge Services

Cutting Solutions

Innovative cutting solutions delivering efficiency and precision, from blade selection to process optimization, ensuring superior performance across applications.

Razor Slitting Solutions

Precision razor slitting services tailored to your needs, ensuring clean and accurate cuts for various materials in industrial applications.

Circular / Shear / Score & Core Blades Services

Comprehensive services for circular, shear, score, and core blades, optimizing cutting processes for enhanced efficiency.

Special Industry Blades Offerings

Customized solutions for specialized industry blades, meticulously designed to meet the unique cutting requirements of diverse sectors with unparalleled precision and efficiency.

Our Process

1

Analysis

Thorough assessment of your cutting needs to identify precise requirements and optimal solutions.

Design

Customized blade design tailored to your specifications, ensuring maximum performance and efficiency.

Manufacturing

State-of-the-art manufacturing processes to produce high-quality blades with precision and consistency.

Testing

Stringent quality testing to guarantee durability, reliability, and superior performance in real-world cutting applications.

Frequently Asked Questions

What materials are suitable for cutting with Three Hole / Euro Razor Slitter Blades?

Our Three Hole / Euro Razor Slitter Blades are versatile and suitable for cutting a wide range of materials including film, foil, paper, and flexible packaging materials.

Can Three Hole / Euro Razor Slitter Blades be sharpened or reconditioned?

Yes, our blades are designed to be sharpened or reconditioned, extending their lifespan and ensuring continued high performance.

How long does it take to receive an order of Three Hole / Euro Razor Slitter Blades?

Stock items are typically shipped within one business day. For custom orders, lead times may vary depending on specifications. Contact our team for more information on delivery times.

What makes Three Hole / Euro Razor Slitter Blades stand out from other options on the market?

Our Three Hole / Euro Razor Slitter Blades are engineered with precision and durability in mind, ensuring consistent, clean cuts and maximum productivity. With state-of-the-art design and manufacturing techniques, they offer unmatched performance and reliability, setting the standard for quality in the industry.