Here is an article from Paper, film & Foil Convertor (pffc-online.com) that we wanted to share:

Manufacturers looking for small quantities of flexible packages are finding that digitally-printed labels are a cost-effective and efficient way to go—with minimum runs of 50. Ensure that label design and content work well when used with flexible packages—addressing pertinent regulations, needed disclosures, informative explanations, branding, and more.

And, pay attention to how well they adhere to the package itself. Confirm that adhesive and the way the labels are applied are appropriate to the process and the package.

Start out by looking at the packaging itself and where it’s traveling. Craig Conner, founder of Denver-based Pablo’s Coffee, points out that “some bags retain shape better than others. We’re working with packaging that’s stiffer. It needs to hold labels.”

He adds that, “Most packages are for us and our stores. They’re not traveling and going on another shelf,” which means less likelihood of label wear and tear. This appears to be an excellent way to sidestep a current coffee brand trend that puts a bag inside a box to ensure maintaining package integrity.

While this move may work to safeguard product and package, it increases use of resources and waste—and requires opening two items instead of one. For those frustrated with trying to open packages, why double the effort?

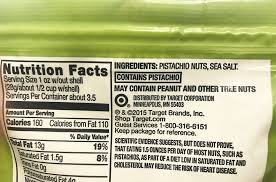

On extremely rare occasion, the proper development and use of labels on flexible packaging can be a matter of life and death—which dramatically documents the importance of doing it correctly and considering all options. Case in point: the teen with a severe peanut allergy who died after consuming Nabisco cookies containing Reese’s peanut butter cups. A USA Today article points out: “Alexi was at a friend’s where her mom believes a folded-back cookie box wrapper in a box of Chips Ahoy! Cookies hid the presence of the allergic ingredient…”

This type of tragedy merits prompting product manufacturers to review flexible packaging and associated labeling from a variety of perspectives, including:

- Regarding regulations in new ways. Using the Nabisco example, think about how any required or even voluntary important information can be positioned so as not to be missed if the flexible package is folded, crumpled or otherwise altered. This well may be a situation where design and branding considerations are secondary to safety and protection. Of course, this isn’t applicable to all products. For example, coffee is unlikely to pose a problem—unless it’s going to be infused or mixed with CBD, beer or other substances where warnings and/or cautions are mandatory or advised.

- Disclosing in detail. Flexible packaging adds a couple wrinkles (literally and figuratively) to detailed disclosures. Often in teeny type to begin with, these disclosures may suffer a loss of readability because of wrinkles in the packaging itself or, if not properly adhered, the labels themselves. Ask, “Where do these disclosures need to be placed to ensure the best viewing opportunity?” Flexible packaging adds a level of complexity to how disclosures are positioned. As part of the label development process, toss the package around, bend it, and otherwise stress it to see what stays in clear view and what is hidden or minimized.

- Informing instead of infuriating. When a manufacturer wants to make sure the consumer is fully informed about the product, contents, or other important facts, discussion about “off-label” ways to do it becomes a priority. If a lot of information merits inclusion, think about use of a QR code or other technology to get people to check it out somewhere other than the label itself. Besides lessening stress on the type size (six-point is better than two-point), it can open up label space for bigger, brighter graphics that won’t disappear so easily when the flexible package is flexed.

- Branding in a can’t-miss way. Regardless of how much label content merits inclusion, strategize ways to make the branding and messaging big, bold and beautiful. As with the information challenge above, this may require transferring at least some content off the label and on to a website or other platform with ample space for explanations and education. For example, if a manufacturer wants to be doubly sure that “gluten-free” is prominently positioned to optimize branding opportunities, then something needs to give. In the case of flexible packaging, you already have a container that may crinkle up and obscure key messaging.

Even when the print run is short, don’t be shortsighted about the importance of making sure flexible packaging and the associated label are all they can be.

Download the full report at https://www.leasefoundation.org/industry-resources/u-s-economic-outlook/. Authors – Gary Paulin and Mark Lusky

Contact Hardedge Tool for all of your Industrial Razor Blade, Converting Blades and Film Slitting Blade needs! (859) 581-0770 FAX: (859) 581-0776