Discovering Hardedge Tool’s Popular Blades: Precision Cutting Solutions for Every Industry

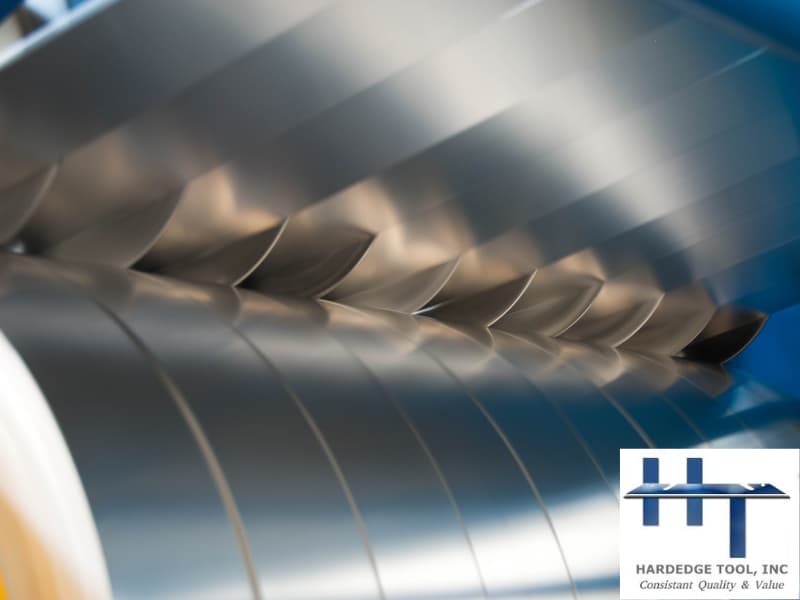

In the ever-evolving world of manufacturing and industrial cutting, the tools used can significantly impact efficiency and quality. At Hardedge Tool, we have been at the forefront of providing high-quality industrial razor blades, slitter blades, and converting blades for over 50 years. Our commitment to precision, quality, and customer satisfaction has made us a trusted partner for a diverse range of industries, including film, foil, food, paper, and flexible packaging. In this blog post, we’ll explore some of our most popular blades and how they can enhance your cutting operations.

1. Titanium Carbide SS 3-Hole Razor Blade

The Titanium Carbide SS 3-Hole Razor Blade is renowned for its exceptional durability and performance. These blades are designed to withstand high wear and tear, making them ideal for continuous operation in demanding environments. The titanium carbide coating provides a hard surface that resists chipping and wear, ensuring that the blade maintains its sharpness longer than standard blades. This results in fewer replacements and lower operating costs.

Applications

This versatile blade is suitable for a wide range of applications, including slitting films, foils, and other materials where precision is crucial. Its three-hole design allows for easy installation and compatibility with various machinery, making it a favorite among operators seeking reliability and efficiency.

2. Carbide 3 Hole Razor Slitter

The Carbide 3 Hole Razor Slitter is another popular choice among our clients. Known for its sharpness and longevity, this blade is engineered for precision slitting tasks. The carbide material ensures that the blade remains sharp even after prolonged use, delivering clean cuts consistently.

Benefits

With its robust construction, the Carbide 3 Hole Razor Slitter minimizes downtime associated with blade changes. This blade is particularly effective in industries where high-speed cutting is essential, such as packaging and textiles. Users can expect enhanced productivity and reduced waste, making it a smart investment for any cutting operation.

3. SS 3 Hole Slitter Blade with Ceramic Coating

For those looking for an advanced cutting solution, the SS 3 Hole Slitter Blade with Ceramic Coating is an excellent option. The ceramic coating not only enhances the blade’s hardness but also provides resistance to corrosion and other environmental factors. This blade is particularly effective in applications that involve cutting abrasive materials, where traditional blades may wear quickly.

Performance Features

The unique ceramic coating allows for smoother cutting edges, resulting in less friction and heat generation during operation. This characteristic not only extends the blade’s lifespan but also improves the quality of cuts, leading to better end products.

4. Solid Ceramic Zirconia Slotted Slitter Blade

The Solid Ceramic Zirconia Slotted Slitter Blade is designed for high-performance cutting in specialized applications. Zirconia is known for its exceptional hardness and resistance to wear, making it perfect for industries that demand precision and durability.

Ideal Uses

This blade excels in cutting ceramics, composites, and other tough materials. Its design reduces the risk of blade breakage, which is critical in high-stakes environments where downtime can be costly. The solid construction ensures that users achieve consistent results, enhancing overall operational efficiency.

5. Solid Tungsten Carbide Slotted Slitter Blade

For heavy-duty applications, the Solid Tungsten Carbide Slotted Slitter Blade stands out due to its superior strength and resilience. Tungsten carbide is one of the hardest materials available, providing exceptional wear resistance and longevity.

Advantages

This blade is particularly effective in high-volume production environments where reliability is essential. Its ability to maintain sharpness over extended periods leads to fewer replacements and minimal disruptions in the cutting process. Industries that handle thick or dense materials will benefit greatly from this robust blade.

6. SS Slotted Slitter Blade with Ceramic Coating (Squared and Rounded Corners)

We offer two variants of the SS Slotted Slitter Blade with Ceramic Coating: squared and rounded corners. Both designs cater to different cutting needs and preferences. The ceramic coating enhances durability, while the choice of corner design allows operators to select the best fit for their specific applications.

Versatility

These blades are ideal for a variety of slitting tasks, from flexible packaging to textile cutting. The squared corners provide precision for straight cuts, while the rounded corners reduce the risk of snagging, making them suitable for more delicate materials.

7. Circular/Shear/Score Blades

Our range of Circular/Shear/Score Blades offers versatility for different cutting operations. These blades are designed for clean, precise cuts across various materials, making them essential tools in industries such as printing, packaging, and textiles.

Key Features

The circular design allows for continuous cutting, which is ideal for high-speed applications. Whether you need blades for shearing, scoring, or circular cutting, Hardedge Tool provides options that ensure optimal performance and longevity.

8. Injector Blades and Special Blades

In addition to our standard offerings, we also provide specialized blades for unique applications. Injector Blades are tailored for specific machinery, ensuring that users achieve the best possible results. Our Special Blades are designed to meet the unique requirements of various industries, providing customized solutions that enhance cutting efficiency.

Conclusion

At Hardedge Tool, our dedication to providing high-quality blades is matched only by our commitment to customer satisfaction. Whether you’re in the film, foil, food, paper, or flexible packaging industry, our popular blades are designed to meet your specific cutting needs. With over five decades of experience, we understand the importance of precision and reliability in cutting operations.

By choosing Hardedge Tool, you’re not just selecting a blade; you’re investing in cutting-edge solutions that will elevate your production processes. Explore our range of popular blades today and discover how we can help you optimize your cutting operations for enhanced efficiency and productivity. For more information, reach out to our expert team, and let us assist you in finding the perfect cutting solutions tailored to your unique needs.

Blog by Foster Group