If you want to streamline your industrial operations and minimize your costs, you must use the correct type of industrial razor blades for your job. Standard single-edged razors are applicable for use on a wide range of applications. Still, if you need a specialized design or more outstanding durability, other options might serve you better.

Industrial razor blade tools are helpful for a wide range of projects, from large manufacturing to do-it-yourself jobs, whether you need to scrape and remove paint, vinyl, or other rigid material. Choosing the right blade can help you improve your productivity and reduce your costs.

Streamline Your Operations

With a standard industrial razor blade tool, you’ll be able to remove paint from metal or wood surfaces quickly and easily. A typical industrial razor blade tool can cut through even tough house siding or vinyl fence, allowing you to remove it without the need for power tools.

Specialty blades often remove rust from metal or other substances from surfaces in manufacturing facilities. In addition, they can get used as a deburring tool to smooth rough edges on manufactured parts. Examples of specialty blades include converting blades and film slitting blades.

When it comes to removing paint, vinyl siding, and other material from surfaces, a single-edge razor blade is often the best option for convenience and effectiveness. With a wide variety of sizes available, and finishes available from which to choose, you can find one that will suit most needs.

What’s So Special About This Type Of Razor Blade?

Industrial razor blades come in different shapes and sizes. Some industrial blades are flat, some are curved, and some even look like an arrowhead! Often, they get manufactured with carbon steel or stainless steel.

Standard industrial blades often contain high-carbon steel, great for many everyday jobs but not as durable as stainless steel. Stainless blades resist corrosion and can last longer. Ceramic blades are another option, and they’re very hard, so they won’t chip like regular blades.

Ceramic blades have been around since the 1950s, when Gillette first introduced them. Ceramics-coated stainless steel blades and solid ceramic zirconia blades are popular choices in industrial applications. The coating helps prevent rusting, while the hardness makes them more effective at cutting.

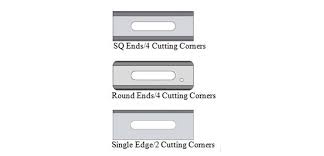

Blades with four square ends and four cutting corners are ideal for cutting sheet metal, such as aluminum. Blades with round ends and four cutting corners work well for cutting thicker materials, such as plywood.

How Long Do Industrial Razor Blades Last?

The length of time that industrial razor blades last depends on their application. For example, they may only need sharpening once every three months, or they could require frequent resharpening. Therefore, you should always check the manufacturer’s instructions before using any new blades.

If you need to ensure that you never run out of sharp industrial razor blades never runs low, consider keeping a set of replacement blades in your inventory of supplies. If you don’t already have a supply of these blades on hand, rely on the professionals at Hard Edge Supply to help you stock up.

Contact Hardedge Tool for all of your Industrial Razor Blade, Converting Blades and Film Slitting Blade needs! (859) 581-0770 FAX: (859) 581-0776