Sharper than You Think: The Science Behind Industrial Cutting-Edge Technology

Industrial razor blades are crucial in various industries, providing precision and efficiency in cutting applications. These technical blades are designed to meet the rigorous demands of industrial processes, from manufacturing and packaging to food processing and medical equipment production. This guide delves into the different types of industrial razor blades, their applications, and the technological advancements driving their development.

Types of Industrial Razor Blades

- Straight Blades: Straight blades are the most ordinary type of industrial razor blades, featuring a simple, flat design with a sharp edge. They are used in various applications, including cutting film, paper, foil, and other materials in manufacturing processes.

- Circular Blades: Circular blades, also known as rotary blades, are used in industries requiring continuous cutting, such as textiles, plastics, and metals.

- Double-Edge Blades: Double-edge blades offer the advantage of having two cutting edges, doubling the blade’s lifespan before replacement is necessary. These blades are commonly used in applications where consistent sharpness and durability are critical, such as in the food processing and medical industries.

- Hook Blades: Hook blades are uniquely designed with a hook-shaped edge, ideal for cutting materials that require a precise initial puncture and subsequent clean slicing. These blades are particularly useful in roofing, flooring, and linoleum cutting, where the hook shape helps easily cut through tough or thick materials.

Applications of Industrial Razor Blades

- Manufacturing: In the manufacturing sector, industrial razor blades are indispensable for cutting various materials, including plastics, rubber, textiles, and metals. They are used in slitting, trimming, and perforating processes, ensuring clean and accurate cuts.

- Packaging: Industrial razor blades are essential in the packaging industry, where they are used to cut and shape materials such as cardboard, paper, and plastic films.

- Food Processing: In the food processing enterprise, industrial razor blades are used for cutting, slicing, and dicing various food products.

- Medical Equipment: The medical industry relies on industrial razor blades to produce surgical instruments, diagnostic tools, and other medical devices

Technological Advancements in Industrial Razor Blades

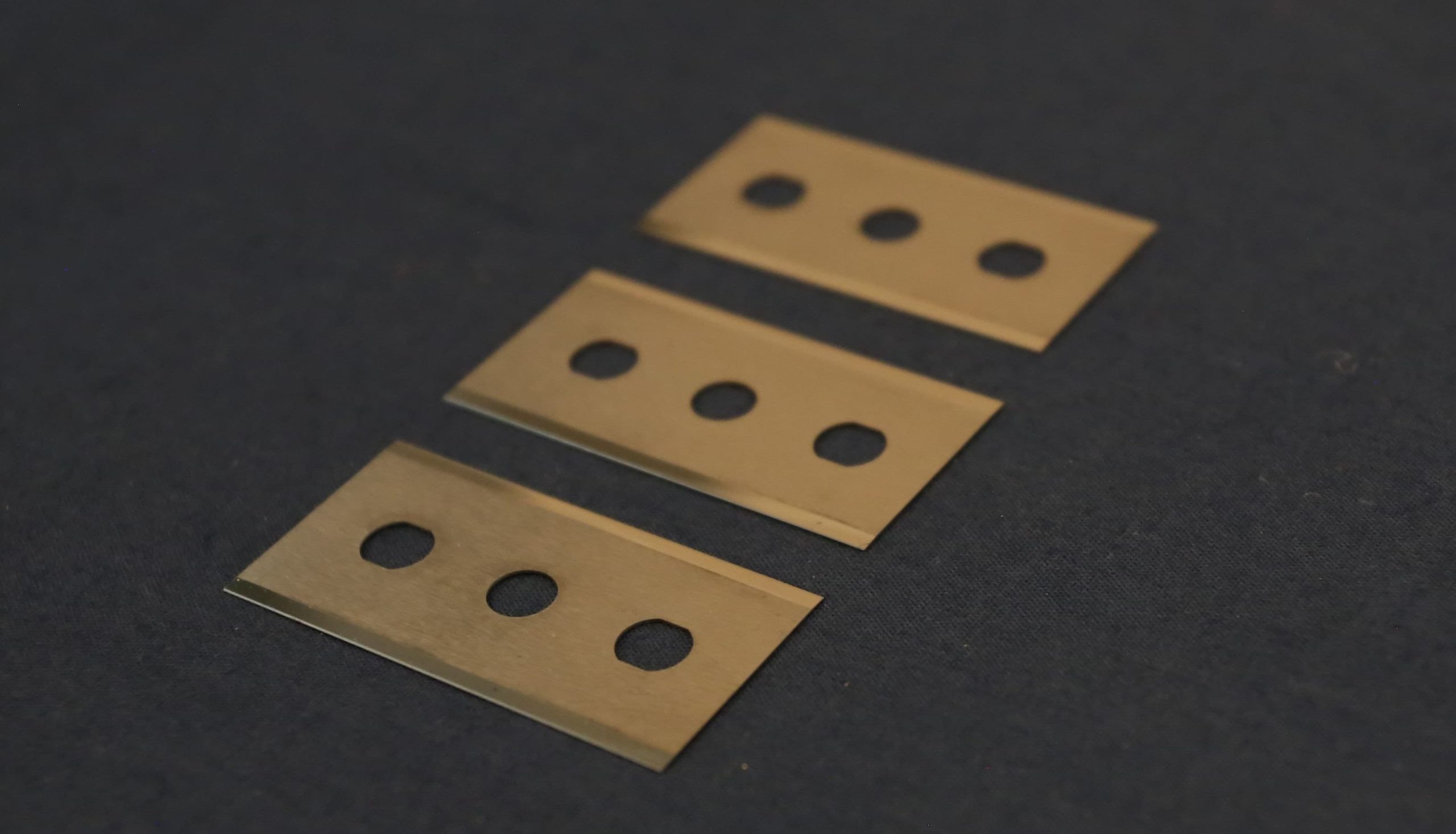

- Material Innovations: Developing new materials has significantly improved the performance and durability of industrial razor blades. High-carbon stainless steel, tungsten carbide, and ceramic are some of the advanced materials used in manufacturing these blades.

- Coating Technologies: Coatings play an integral role in enhancing the performance of industrial razor blades. Advanced coatings such as titanium nitride, diamond-like carbon, and ceramic coatings provide additional hardness, reduce friction, and increase resistance to wear and corrosion.

- Precision Manufacturing: Precision manufacturing techniques, including CNC machining and laser cutting, have revolutionized the production of industrial razor blades. These techniques allow for blades with extremely tight tolerances and consistent quality.

- Automation and Smart Technologies: Integrating automation and smart technologies in producing and using industrial razor blades has significantly improved efficiency and accuracy. Automated machinery with sensors and control systems can optimize the cutting process, reducing material waste and improving production speed.

Best Practices for Using Industrial Razor Blades

- Proper Installation and Handling: Ensuring that industrial razor blades are correctly installed and handled is essential for their performance and longevity. Handling blades carefully and using appropriate tools and protective equipment will prevent damage and ensure safety.

- Regular Maintenance and Inspection: Regular maintenance and inspection are crucial for maintaining the sharpness and effectiveness of industrial razor blades. Establishing a routine maintenance schedule, including cleaning, sharpening, and checking for signs of wear, will extend the lifespan of the blades and ensure consistent cutting performance. Keeping detailed records of maintenance activities can help identify patterns and improve maintenance strategies.

- Sharpening and Replacement: Knowing when to sharpen or replace industrial razor blades is critical for maintaining cutting quality. Dull blades can cause poor cuts, increased material waste, and potential damage to machinery. Monitoring blade sharpness and performance and having a timely sharpening or replacement system will help avoid these issues. Utilizing professional sharpening services or investing in high-quality sharpening equipment can also improve blade maintenance.

- Safe Disposal: Proper disposal of used industrial razor blades is important for environmental and safety reasons. Implementing a disposal protocol that includes safe handling, packaging, and disposal of blades will prevent accidents and reduce environmental impact. Recycling programs for metal blades can also contribute to sustainability efforts by reducing waste and reclaiming valuable materials.

Conclusion

Industrial razor blades are indispensable tools in numerous industries, offering precision, efficiency, and reliability in cutting applications. The continuous advancements by Hardedge Tools in materials, coatings, manufacturing processes, and digital integration are driving the evolution of these blades, making them more effective and sustainable. By adopting the best blade installation, maintenance, and disposal practices and staying informed about future trends, businesses can optimize their cutting operations and achieve greater productivity and success.

As industries move towards more specialized and sustainable practices, the role of industrial razor blades will persist and evolve, meeting the ever-changing demands of modern manufacturing and processing. Investing in high-quality blades and staying abreast of technological advancements will ensure businesses remain at the cutting edge of their respective fields.